|

UNIPRETEC CERAMIC TECHNOLOGY

|

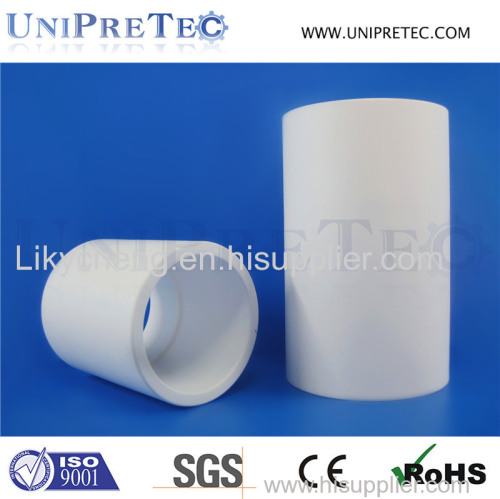

Al2O3 Ceramic Lined Pipe Alumina Ceramic Lining

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,Paypal |

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Aluminium Oxide, Al2O3 is the most widely applied and cost effective technical ceramic material. It offers a combination of superior mechanical streng

Al2O3 Ceramic Lined Pipe Alumina Ceramic Lining

Specification:

*Good thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Temperature resistance up to 1700°C

Product Description

Material introduction:

Aluminium Oxide, Al2O3 is the most widely applied and cost effective technical ceramic material. It offers a combination of superior mechanical strength and electrical properties, wear resistance and corrosion resistance. The maximum working temperature is up to 1700 °C with relatively high thermal conductivity. It is also an electrically insulating material with a high electrical resistivity. The good corrosion resistance makes it insoluble in water and slightly soluble in strong acid and alkaline solution.

Available shapes:

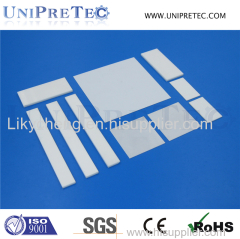

Our Alumina Ceramic products can be made into different shapes like ceramic rods, ceramic bars, ceramic tubes/tubings, ceramic bushings/ceramic bushing, ceramic sleeves, ceramic seal rings, ceramic washers, ceramic ball valves, ceramic pistons, ceramic disks, ceramic plates/sheets/substrates or other customized shapes.

According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.